As solar + storage installations continue to expand across residential and commercial projects, electrical safety, load management, and system coordination have become essential components of modern energy design. One of the biggest advancements addressing these needs is the introduction of Power Control Systems—a technology now formally recognized and regulated under the National Electrical Code (NEC). Specifically, NEC 705.13 outlines the rules and expectations for using PCS in interconnected solar, battery, and hybrid energy systems.

For solar installers, engineers, and permitting professionals, understanding PCS is no longer optional. It’s now a key element in designing code-compliant systems, avoiding expensive service upgrades, and ensuring the safe coexistence of multiple energy sources on a single electrical service.

This guide breaks down what Power Control Systems are, why NEC 705.13 matters, and how PCS compliance affects your solar project.

What Are Power Control Systems (PCS)?

Power Control Systems are intelligent energy management solutions that monitor and automatically limit the output of solar inverters, battery systems, and other distributed energy sources to ensure that the total delivered energy never exceeds the capacity of the electrical service.

In simpler terms:

PCS keeps your home or building from being overloaded by controlling how much power your solar, battery, or generator can send to the electrical panel.

These systems play a crucial role in:

- Managing power sources in real time

- Preventing overloads

- Avoiding costly service upgrades

- Ensuring NEC compliance

With solar installations becoming larger and more complex, PCS technology has become essential for safe and efficient system operation.

Why NEC 705.13 Matters

The National Electrical Code added NEC 705.13 to define how Power Control Systems must operate when used in interconnected power sources (such as solar + battery). This section ensures that energy systems remain safe, coordinated, and compliant—especially when total system output might exceed the load center or service rating.

NEC 705.13 is important because it:

- Provides a clear pathway for using PCS as part of system design

- Helps installers avoid main service upgrades

- Requires real-time monitoring and output limiting

- Ensures that PCS-listed equipment performs safely under all conditions

For anyone designing solar systems today, PCS compliance has become a major factor in approval and long-term safety.

Key Requirements of NEC 705.13

To meet PCS compliance, a system must follow several important rules defined by NEC 705.13. Here are the major components:

1. Real-Time Monitoring and Control

A PCS must actively monitor all connected energy sources and automatically limit output to stay within the service rating. Manual control or offline adjustments are not enough for compliance.

2. Automatic Response to System Changes

If multiple power sources (solar, battery, generator) are operating, the PCS must automatically adjust output to avoid exceeding allowable limits. This continuous control ensures a stable and safe load.

3. Fail-Safe Operation

If the PCS stops communicating or fails for any reason, NEC 705.13 requires the system to:

- Reduce output

or - Disconnect generation sources

This protects the panel and conductors from overload.

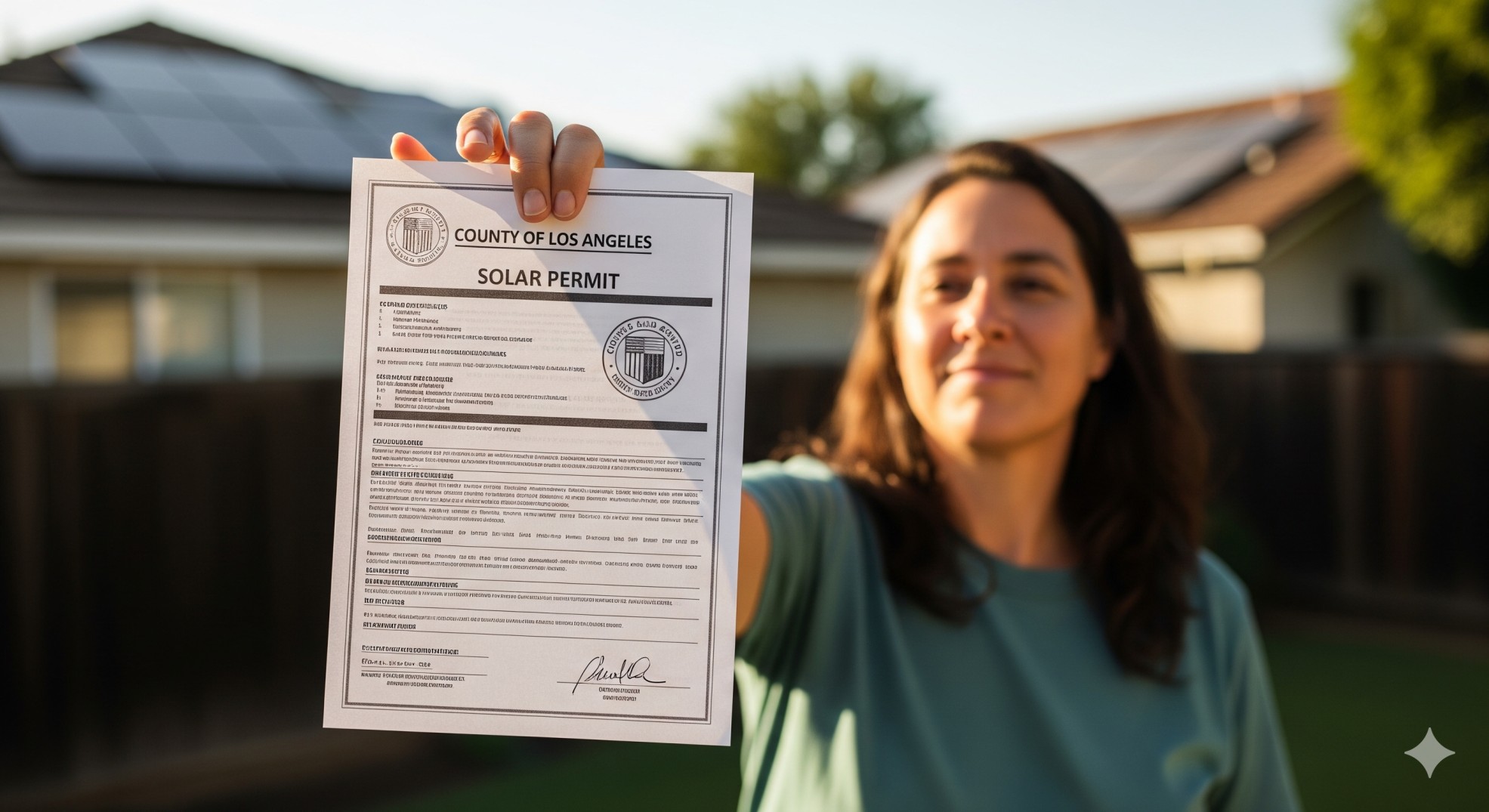

4. Listed and Documented Equipment

Equipment used as a Power Control System must be:

- Listed for PCS functionality

- Clearly labeled

- Documented in system diagrams

AHJs (Authorities Having Jurisdiction) rely heavily on documentation to verify PCS compliance during permits and inspections.

5. Integrated Into the System Design

PCS cannot be a simple add-on. The design must clearly show:

- PCS functionality

- Controlled circuits

- Maximum permitted power output

- How the PCS maintains NEC 705.13 compliance

This makes PCS a core part of engineering—not an afterthought.

How PCS Helps Avoid Service Upgrades

One of the most practical advantages of using Power Control Systems under NEC 705.13 is the ability to install larger solar and battery systems without upgrading the main electrical service.

For example:

A home with a 100A or 125A service may not be able to support a large solar system under traditional backfeed rules. However, by using PCS to limit output automatically, installers can:

- Maintain safe system limits

- Meet all NEC requirements

- Bypass expensive service upgrades

This can save homeowners thousands of dollars while still allowing high-capacity solar + storage systems.

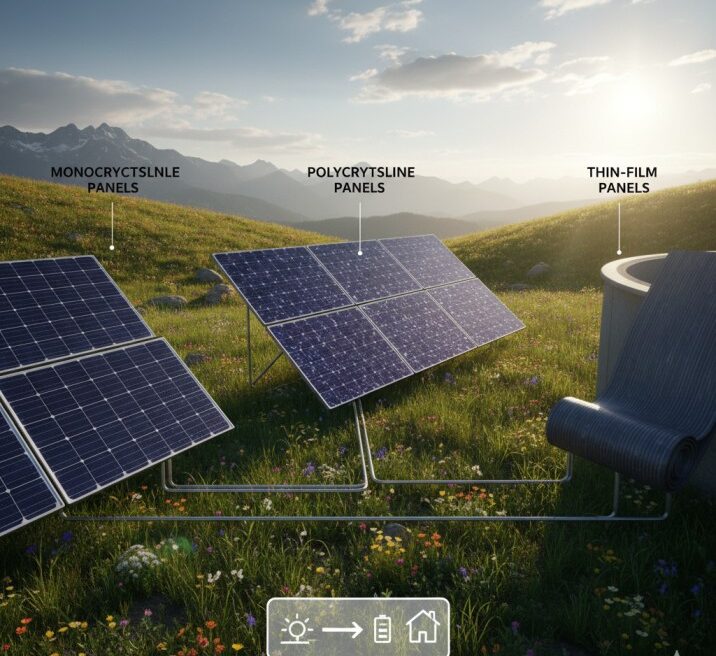

Where PCS Is Commonly Used

PCS technology is becoming standard in a variety of solar and hybrid installations, including:

- Hybrid inverter systems

- Solar + battery storage projects

- Homes with limited service capacity

- Commercial buildings with multiple energy sources

- Properties integrating EV chargers with solar

- Systems requiring export limiting or load control

As energy requirements grow, PCS will continue to play an important role in ensuring system safety and efficiency.

FAQs About Power Control Systems and NEC 705.13

1. Is a PCS required for all solar installations?

No. PCS is needed when combined energy sources exceed the service or busbar rating, or when load control is required for safe operation.

2. Does using PCS eliminate the need for a service upgrade?

In many cases, yes. PCS can reduce or limit output so the system remains compliant without increasing the service size.

3. Is PCS built into some inverters?

Some modern hybrid inverters include PCS functionality, but they must be officially listed and documented as PCS to meet NEC 705.13 requirements.

4. Do inspectors check PCS documentation?

Yes. AHJs typically require clear documentation showing PCS operation, settings, and compliance with the National Electrical Code.

5. Can PCS work with solar and battery systems together?

Absolutely. PCS is specifically designed to coordinate multiple distributed energy resources safely.